High-Performance Materials for High-Stakes Industries.

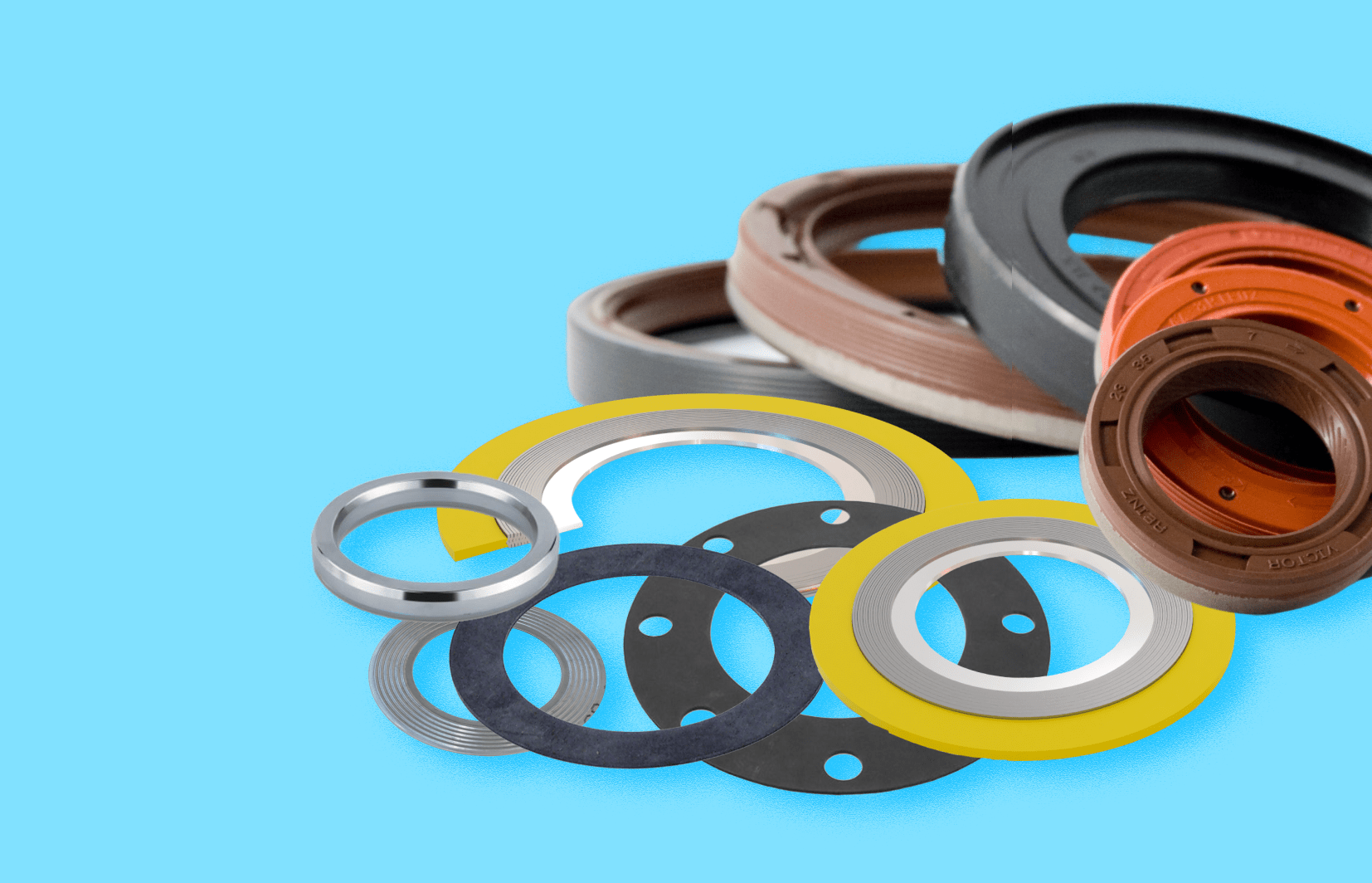

The difference between equipment success and failure often comes down to one critical component: the seal or gasket protecting your system from the elements. When you work in oil & gas, chemical processing, or water and wastewater treatment, your equipment doesn't get an easy day. Extreme heat, corrosive chemicals, pressure fluctuations, and environmental exposure can all work against the reliability of your seals and gaskets.

The wrong choice of material can lead to premature failures, unplanned downtime, and costly maintenance cycles. The right choice can mean years of dependable service, improved safety, and a better return on your investment. In this post, we'll break down how to choose the right seal or gasket material for harsh environments and point you to resources that go deeper into each material's capabilities.

Understand the Forces at Work in Harsh Environments

Temperature Extremes

Both high and low temperatures can impact elasticity, compression set, and sealing ability.

Chemical Exposure

Acids, solvents, fuels, and aggressive cleaning agents can degrade materials.

Pressure Cycles

Rapid or repeated changes in pressure can cause mechanical wear or blowouts.

Weather and UV

Outdoor exposure to sun, wind, and moisture can accelerate breakdown. For more on how weather specifically affects sealing performance, read our post on Weather's Impact on O-Rings.

Match the Material to the Application:

PTFE (Polytetrafluoroethylene)

Best for

Extreme chemical resistance, wide temperature range.

Advantages

Handles aggressive acids, bases, and solvents; stable from -450°F to +500°F.

Use Cases

Chemical processing lines, high-purity water systems.

Graphite

Best for

High temperature sealing in corrosive or oxidizing environments.

Advantages

Thermal stability beyond 800°F, excellent load-bearing capacity, self-lubricating properties reduce friction and wear.

Use Cases

Steam applications, refinery flanges, high-pressure systems, turbine seals.

Fluoroelastomers (e.g., Viton®)

Best for

Resistance to fuels, oils, and a wide variety of chemicals.

Advantages

Maintains flexibility in high heat, resists swelling and degradation.

Use Cases

Oilfield equipment, chemical seals, outdoor gaskets.

Learn More

Getting to Know Fluoroelastomer

Spiral Wound Gaskets

Best for

High-pressure, high-temperature flange sealing.

Advantages

Combines metal strength with soft filler adaptability, reusable in some cases.

Use Cases

Pipeline flanges, petrochemical plants, power generation.

Learn More

Getting to Know Spiral Wound Gaskets

When choosing between common elastomers like fluoroelastomer and nitrile, the material selection can determine whether your seals last months or years. For a detailed comparison, see our guide: Viton® vs. Nitrile.

Consider the Total Cost of Ownership

While high-performance materials often cost more upfront, they may outlast standard materials by 2-3 times. That means fewer replacement cycles, less downtime, and lower costs.

Partner with an Expert

Material selection isn't a one-size-fits-all decision. Partnering with an experienced sealing solutions provider like APG means you get:

- Engineering support for material selection.

- Application-specific recommendations.

- Proven products tested in the same environments you work in every day.

The Bottom Line

Harsh environments will always test the limits of your equipment. With the right seal or gasket material, you can make sure your operation passes that test every time.

Tough jobs need tougher materials.

Explore APG's Extreme-Duty Solutions →

+1 800-888-5223

+1 800-888-5223

.png?width=352&name=PTFE%20(1).png)

.png)