Trade Names: Viton (E.I. DuPont), Fluorel (3M)

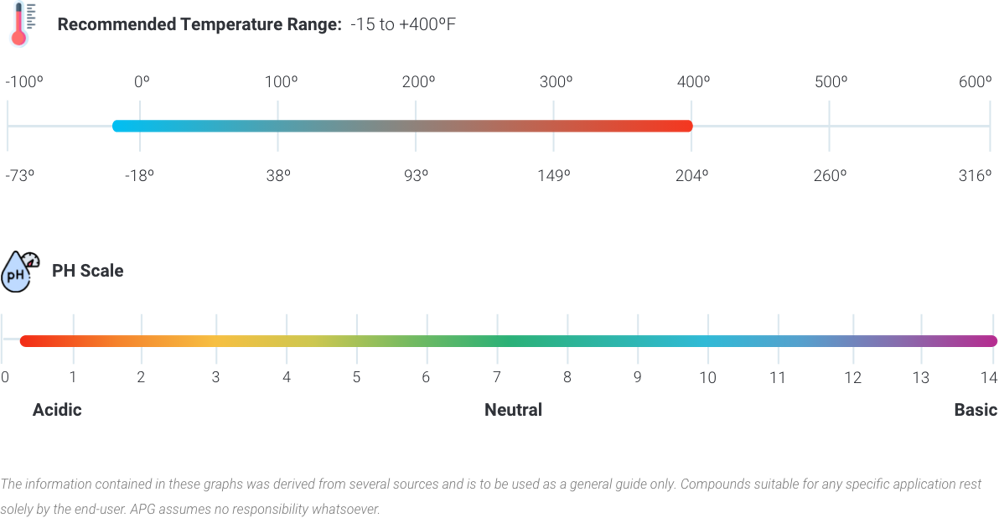

Fluoroelastomer rubber (Viton) performs well in many different environments such as a variety of oil and petroleum products, high vacuum situations, ozone, weather, high temperatures, and strong acids. This material is commonly used to seal leaks, valves, or pumps. Fluoroelastomer (Viton) has a high resistance to petroleum products as well as a super-low compression set. This makes them a good choice for handling and transporting chemicals and fuels. Has a wide spectrum of chemical compatibility.

Harsh Conditions

Viton performs well in some of the harshest conditions an O-Ring could face. Extremely high temperatures, harsh chemicals, and high oxygen environments. Fluoroelastomer is super resistant to any sort of abrasion or tearing that may occur and the application it is used in whether it is from an o-ring or a gasket.

Oil & Petroleum Use

One of the industries that use this material is the oil and petroleum industry. Viton ® has good resistance to most oils, crude, gasoline, and petroleum. This includes vegetable oils, alcohol, hydraulic oils, and much more.

Acetone, Methyl, Organic Acids

Despite Viton ® being super resilient against almost anything that is thrown at it, it does have a few disadvantages that could easily damage or destroy the material. Any type of ketones like acetone, ethyl-based acetate, amines, and any sort of organic acids. These can cause the elastomer serious damage and will cause the o-ring to fail.

+1 800-888-5223

+1 800-888-5223

.png?width=352&name=Which%20O%20ring%20works%20best%20for%20your%20industry%20(1).png)

.png)