Once you have confirmed that your lubricant is safe for use with both your O-Ring and your application, it is a good practice to double-check the o-ring size. The wrong size can lead to a damaged seal, poor performance, or a damaged system.

Rubber o-rings are essential for a wide variety of fluid power applications. It’s necessary to ensure that a seal is the right size and has been designed with the application in mind. Even when you have a high-quality o-ring that is the appropriate size and material for the application, if installed inappropriately, the seal can fail prematurely, leading to leaks and potentially catastrophic system failure.

Follow these guidelines to install an o-ring properly. The seal should be well lubricated to make installation as simple as possible. Once you have confirmed that your lubricant is safe for use with your o-ring and your application, it is a good practice to double-check the o-ring size. The wrong size can lead to a damaged seal, poor performance, or a damaged system.

Step 1: Lubrication

APG highly recommends lubrication for o-ring installation. We recommend this because a well-lubricated o-ring reduces surface friction and creates a smooth transition for installation. It is essential to choose the right lubricant, and the proper formula will vary based on the type of application as well as the o-ring material. Choose a lubricant that will work with your application and the o-ring.

Compatibility with your application is crucial because you don’t want to clog the system filters or cause other complications. Choosing a lubricant compatible with your o-ring will ensure that it does not shrink or swell, influencing how it performs once installed. Compatibility with your application is also essential because choosing a lubricant compatible with your o-ring will ensure that it does not shrink or swell, influencing how it performs once installed.

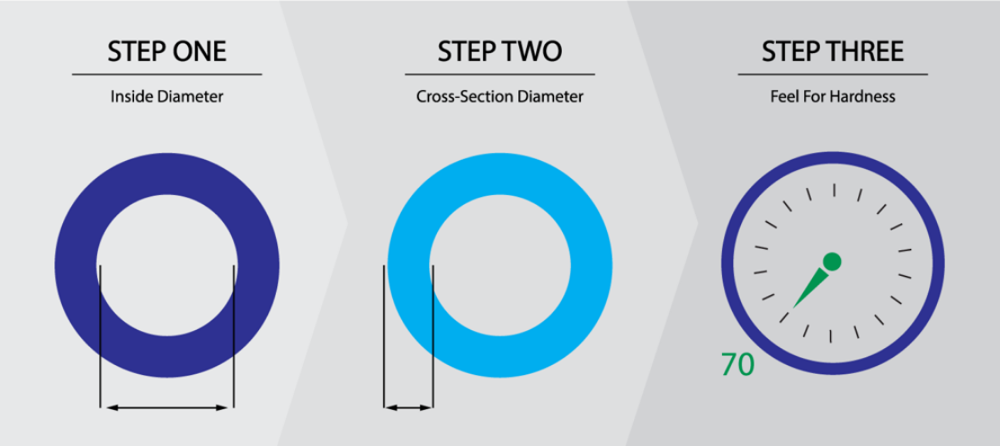

Step 2: Confirm Sizing

Once you have confirmed that your lubricant is safe for use with your O-Ring and your application, it is a good practice to double-check the o-ring size. The wrong size can lead to a damaged seal, poor performance, or a damaged system.

Step 3: Installation

Once you have verified the lubricant compatibility and size, you are ready to place the o-ring. If necessary, cover any sharp edges during the installation process to avoid damage to the o-ring. Lightly lubricate the o-ring and place it in the groove, sliding it, not rolling it into place. In some instances, special o-ring tools can help to properly place an o-ring that cannot be easily placed by hand. A well-placed o-ring should be slightly stretched before application, but don't over-stretch it. This stretch should be between 1-5%, with 2% ideal for most applications.

APG Offers a Great O-Ring Selection and Support

As you can see, installing an o ring is not difficult. It just must be done carefully to avoid overstretching or damage. APG is proud to manufacture and distribute o-rings in standard and custom sizes, or a custom o-ring kit. We hope you will take the opportunity to shop our selection now. We also offer support for all APG-purchased products.

Need o-ring installation support?

Contact APG Today!

+1 800-888-5223

+1 800-888-5223

.png)