The Basics of Compression Pump Packing Installation

The 5 P's of Pump Packing Installation

Installing compression pump packing can be a challenge. Proper installation and adjustment of a packed gland can have a big impact on the reliability, maintenance and operation of your centrifugal pump. With proper installation and packing adjustment you will decrease flush water usage, decrease shaft sleeve wear, increase bearing life and decrease overall maintenance costs.

Learn More on Knowledge Base →

In this article, we will discuss the 5 P's in pump packing to ensure an easy installation new packing material inside the stuffing box of a pump or valve.

Proper Selection of Pump Packing Materials

APG offers several braid configurations, packing fibers, and materials readily available to be shipped to you. Choosing the correct one can be intimidating and confusing. If an equipment manufacturer has not provided guidance or specifications, how can you choose the correct materials? APG has made it easy to learn about all of our materials in an easy to read guide.

The FSA (Fluid Sealing Association) recommends using the acronym STAMPS as the key to choose the right material.

- Size: What is the stuffing box dimensions?

- Temperature: What is the max operating temperature of the medium?

- Application: What type of equipment is it?

- Media: What is the internal pressure being sealed?

- Pressure: What is the internal pressure being sealed?

- Shaft Speeds: What is the surface speed of the shaft?

In using STAMPS, you go over all the possible functions of the equipment such as media, temperatures, pressures, and shaft speeds.

Preperation of the Stuffing Box

Once choosing the correct material, the next step is to ensure the pump and pump accessories are prepared for installing the compression packing. The stuffing box must be clean and worn out packing material must be completely removed. Failure to remove all left-over pump packing can result in uneven seating, which can cause leakage or clogs and lead to overheating issues.

Check the stuffing box’s condition and inspect the shaft and sleeve for wear and tear damage, cracks, corrosion, or other defects. Any damage could result in a shorter lifespan of the pump packing and limit operational life of the pump. A damaged shaft pr sleeve will not allow the packing materials to function properly causing a shorter life span and leakage.

Packing Length and Form

The next step is to determine the length that needs to be cut for the pump as well as the type of cut needed. When determining the length of the packing, do not use a used packing ring as it could result in an improper cut length. This is because a used packing ring could be damaged, stretched, or shrunk during its lifespan. Cutting the ring to short could leave gaps in the seal and cutting it to long will not fit into the stuffing box

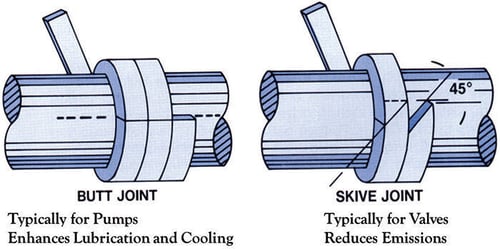

There are two ways to cut the pump packing material for installation. The “butt” cut is a straight-line cut. This type of cut is usually used for pumps and enhances lubrication and cooling. The “Skive” cut is a 45º angle cut which is used mostly in valves and reduces emissions.

Learn About The 8 Packing Fibers →

Placement

Allow time for the pump packing to set and break in. This can take some time and often requires some adjustments of the gland follower. Ensure, the packing is not overtightened as this can call friction and overheating which can damage the packing. Liberal leakage during the first two hours of operation will result in an excellent packing job and help it function for a longer period.

If you feel the packing is not tight enough, gradually tighten it until leak rates stabilize. Check every few hours and adjust the tightness until the leak rate is to the desired level. Ensure the temperature is not high as this could indicate the packing is to tight.

Patience

Allow time for the pump packing to set and break in. This can take some time and often requires some adjustments of the gland follower. Ensure, the packing is not overtightened as this can call friction and overheating which can damage the packing. Liberal leakage during the first two hours of operation will result in an excellent packing job and help it function for a longer period.

If you feel the packing is not tight enough, gradually tighten it until leak rates stabilize. Check every few hours and adjust the tightness until the leak rate is to the desired level. Ensure the temperature is not high as this could indicate the packing is to tight.

APG Wants to be Your Compression Pump Packing Supplier

APG offers several materials, fibers, and configurations readily available in 1 LB, 5 LB, or 10 LB boxes. If you need help choosing the correct pump packing material, please visit our materials section blog or contact an APG expert. Thank you.

+1 800-888-5223

+1 800-888-5223

.png)