Trade Names: Nordel (E.I. DuPont), Royalene (Uniroyal), Epsyn (Copolymer Rubber), Vistalon (Exxon Mobil), Epcar (B.F. Goodrich)

Ethylene Propylene, referred to as EPDM or EP, is a copolymer of both ethylene and propylene and can be also referred to as Ethylene Propylene Diene Monomer. This elastomer is a good compound for sealing phosphate-ester-based hydraulic fluids, glycol brake fluids, and Skydrol® fluids, which are commonly used in commercial aircraft hydraulic systems. EPDM rubber gives excellent resistance to water, steam, ozone, weathering, and UV sunlight. Not all use cases are great with this material as exposure to petroleum-based fluids and di-ester lubricants will eat away at the material causes the seal and system to fail.

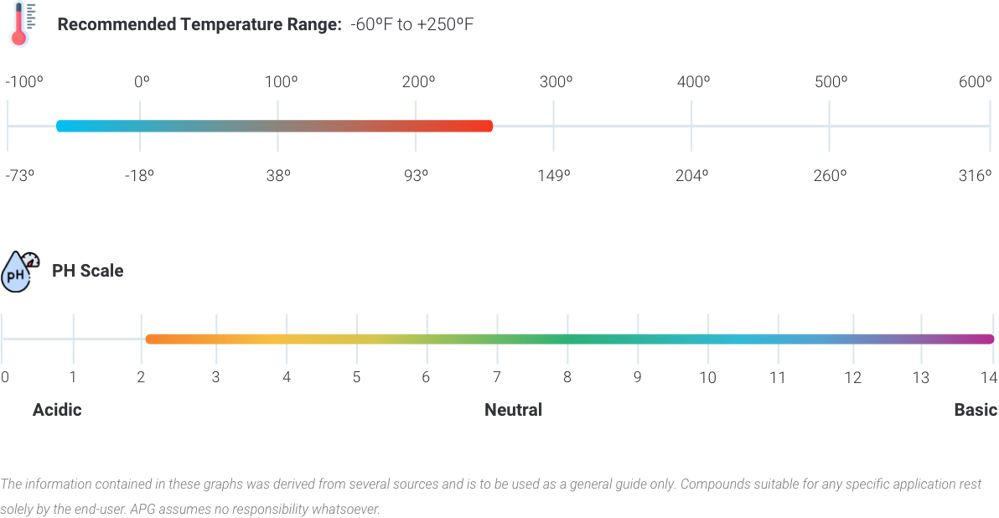

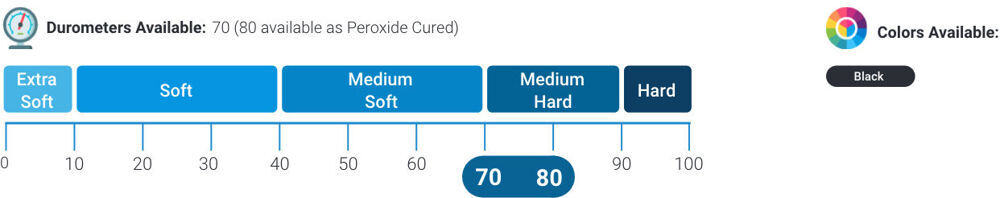

The standard temperature range of EDPM rubber is -60ºF (-50ºC) up to +250ºF (120ºC) and can be made to withstand steam up to +300ºF (150ºC). With proper storage this material can last an infinite number of years stored away. APG stocks the durometer ,70 and 80, contact us if you need a softer or harder rubber.

Industrial uses

- Automotive: Brake systems, cooling systems, low torque belts, and weather stripping.

- Industrial: Water system o-rings, gaskets, connectors for wires and cables, and electrical insulators.

- Construction: Expansion joints, roofing, HVAC systems, and water-tight applications.

- Medical: Respiratory equipment, pumps, IV components, and drug delivery devices.

Temperature Range

EPDM has one of the best temperature ranges in the world of elastomers. Capable of withstanding arctic cold temperatures of -60ºF to a super hot +300ºF. This wide range of temperatures makes this material great for industrial applications in freezers. Storage areas that often change temperatures, and much more.

Chemical Resistance

EPDM has great resistance to steam, sodium hydroxide, diluted acids, detergents, and other base-heavy chemicals. Chemicals such as Acetone, Ammonium Hydroxide, Salt Water, 20% Phosphoric Acid, and 37% cold Hydrochloric Acids, can be sealed using EPDM O-Rings or gaskets. These chemicals have little to no effect on the rubber itself. Other chemicals include polar fluids, polar solvents, alkaline cleaning products, alcohols, and steam.

Petroleum

One major disadvantage with EPDM is its poor resistance to most petroleum-based fuels, oils, and other non-polar solvents. This being said we cannot recommend this material for any petroleum-chemical application such as Gasoline, Fuel Oil, Natural Gas, Mineral Oil, Propane, and Petroleum. If you are looking for a great material for use with oil and other petroleum-based products, Viton or Nitrile would offer superior resistance.

+1 800-888-5223

+1 800-888-5223

.png)

.png)