The O-Ring: A Century of Innovation and APG’s Legacy in Sealing Solutions

Published by American Packaging and Gasket (APG) | July 31, 2025

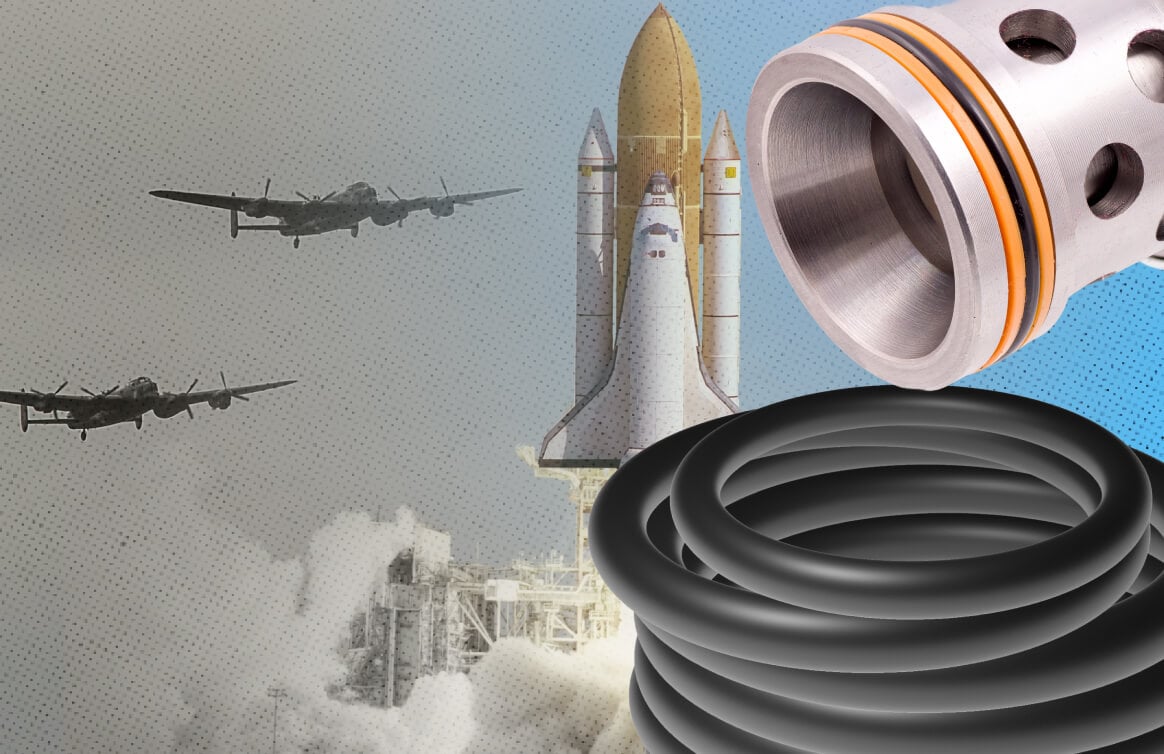

At first glance, an O-ring might seem like a small, unremarkable component. But it’s one of the most vital and versatile parts of modern engineering. For nearly a century, O-rings have provided reliable sealing solutions across countless industries. And since 1943, APG has proudly played a key role in delivering high-performance O-rings to meet the evolving demands of manufacturers, engineers, and technicians around the world.

A Brief History of the O-Ring

Although commonly associated with wartime innovation, the O-ring was invented in 1936 by Danish-American Niels Christensen. As industries ramped up production during World War II, demand for reliable sealing mechanisms surged, and the U.S. government acquired Christensen’s patent to support the war effort.

The design was elegantly simple - an elastomeric loop with a circular cross-section, compressed between components to create a durable seal. That simplicity is why the design has stood the test of time, even as materials and manufacturing processes have become increasingly sophisticated.

Learning from Failure: The Challenger Wake-Up Call

The importance of O-rings became tragically clear in 1986 with the space shuttle Challenger disaster, caused in part by a failed Dupont Viton O-ring that lost flexibility in unusually cold temperatures before launch. The tragedy served as a turning point for the industry. Since then, material science, quality tracking, and rigorous testing have transformed how O-rings are produced and used. APG has embraced these advancements and expanded on for decades.

Meeting Modern Demands with Advanced Materials

Today, O-rings support everything from oil fields and hydraulic systems to dental implants and beverage dispensers. And they’re no longer one-size-fits-all. At APG, we offer O-rings made from a range of high-performance materials to handle extreme temperatures, corrosive chemicals, and complex mechanical requirements, including:

- Aflas

- Neoprene/Chloroprene

- Ethylene Propylene (EPDM)

- Fluoroelastomer (FKM)

- Fluorosilicone

- Nitrile (NBR)

- PTFE

- Silicone

- Urethane/Polyurethane

This versatility makes O-rings one of the most reliable fluid sealing products available and our customers rely on us to help them choose the right material and configuration for their specific needs.

80+ Years of Expertise at Your Service

Since our founding in 1943, APG has evolved alongside our customers. What began as a regional gasket supplier has grown into a globally recognized provider of fluid sealing and conveyance solutions. We understand that today’s industrial challenges require more than just parts they require trusted partners who can deliver quality, speed, and technical support.

We’ve built our reputation by responding to customer needs. Whether it’s navigating supply chain challenges, custom engineering a part, or delivering on tight timelines. Our ISO 9001-certified manufacturing process ensures the quality and traceability you expect, and our experienced team is here to support you every step of the way.

Let’s Talk About Your Sealing Needs

Whether you're looking for a reliable replacement O-ring or engineering support for a complex sealing challenge, APG is ready to help. With more than 80 years of experience and a commitment to quality, we’re proud to be the supplier of choice for leading manufacturers across industries.

Contact us today to speak with a product specialist, request a quote, or explore material options. Let APG be your go-to partner for O-rings and beyond.

Call: 1-800-888-5223

Sales: sales@callapg.com

For more information on APG O-rings, visit APG’s Industrial O-Rings

+1 800-888-5223

+1 800-888-5223

%20(1).png?width=352&name=Top%20Questions%20asked%20about%20vulcanized%20o%20rings%20(2)%20(1).png)

.png)