Rubber seals are an integral part of many systems and devices, serving a variety of purposes such as keeping out dust, moisture, and other contaminants. However, like all materials, rubber can be affected by changes in temperature, and it is important to understand how these changes can impact the performance and durability of rubber seals. In particular, cold temperatures can have a significant effect on rubber seals, and it is important to take steps to protect them in order to maintain their performance and extend their lifespan.

What Happens When Rubber Seals Freeze?

One of the main ways that cold temperatures can affect rubber seals is by causing them to become stiff and brittle. This can occur because the cold temperatures cause the rubber to contract, which can lead to the development of cracks and other types of damage. In addition, cold temperatures can also cause the rubber to become more prone to tearing and ripping, which can further weaken the seal and make it less effective at performing its intended function.

How to Prevent Rubber Seals from Freezing

To prevent these types of problems, it is important to take steps to protect rubber seals from cold temperatures. This can involve storing the seals in a warm, dry place, and taking steps to insulate them when they are in use. For example, if a rubber seal is being used in a system that is exposed to cold temperatures, it may be helpful to wrap it in insulation or use a heating element to keep it warm.

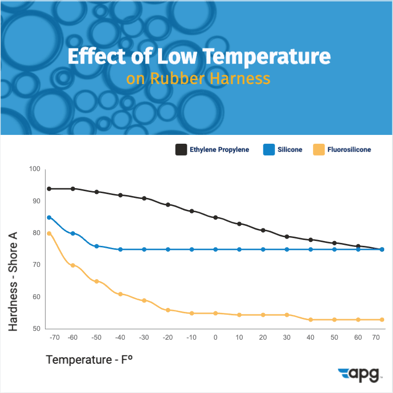

Another way to protect rubber seals from cold temperatures is to use special types of rubber that are designed to be more resistant to the effects of cold. There are many different types of rubber that are specifically formulated to be more resilient to cold temperatures and using these materials can help to extend the lifespan of the seal and improve its performance.

In summary, cold temperatures can have a significant impact on rubber seals, causing them to become stiff and brittle and making them more prone to damage. To protect against these problems, it is important to take steps to insulate and protect rubber seals, and to use special types of rubber that are designed to be more resistant to the effects of cold. By following these steps, you can help to ensure that your rubber seals remain in good condition and continue to perform their intended function even in cold temperatures.

Which Rubber Materials does APG Recommend for Cold Weather?

Silicone is great for sealing in static applications and can be used in the arctic cold weather without losing elasticity or memory. Silicone has been tested to work in environments as low as -62ºC (-80ºF) and can go even lower if made with special compounds. Silicone is great also for sealing chemicals, many different oils and fluids, and petroleum and hydrocarbon-based fuels.

Temperature range: -80ºF (-62ºC) to 450ºF (232ºC)

Pros: Wide temperature range, low compression set, highly flexible, and can be exposed to outside elements such as UV light, sun light, rain, snow, and ozone.

Cons: Low tensile strength, poor tear resistance, and poor wear resistance

Silicone Material Facts >

Nitrile can be a great low-cost material for sealing in low temperatures, however it is prone to shrinking and losing some chemical resistance in those artic temperatures.

Temperature range: -40ºF (-40ºC) to 250ºF(121ºC)

Pros: High compression set, good tensile strength, and great chemical and oil resistance.

Cons: Cannot be exposed to UV light, sun light, rain, snow, or ozone

Nitrile Material Facts >

PTFE can be used in places where compression set is not important. Offers outstanding cold resistance and is unaffected by virtually every oil, chemical, solvent, and alkali known.

Temperature range: -328ºF (-200ºC) to 500ºF (260ºC)

Pros: Highly resistant to corrosion in chemicals or oils and can be exposed to outside elements such as UV light, sun light, rain, snow, and ozone.

Cons: Does not return to its original shape after being bent

PTFE Material Facts

Backed by Decades of Expertise

At APG, we are experts in the field of rubber seals and sealing products. Our team has extensive knowledge and experience in this industry, and we are committed to providing our customers with the highest quality products and services. We offer a range of services, including custom bagging, vulcanizing o-rings, and cutting custom gaskets to meet the specific needs of our customers.

With our expertise and dedication to customer satisfaction, you can trust that we will provide you with the best solution for your sealing needs. Contact us to get a quote today!

+1 800-888-5223

+1 800-888-5223

.png)