Technical Sheet

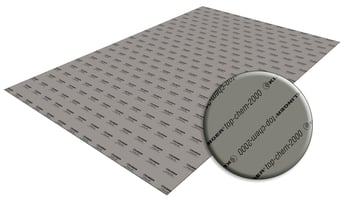

APG's top-chem 2000 is a universal heavy-duty gasket material which offers exceptional performance in applications with high mechanical requirements at high temperatures. It is the only PTFE gasket material with a Fire-Safe Certificate. Use APG's top-chem 2000 in strongly acidic and alkaline applications as well as in steam and oxygen. Suitable for an extremely wide range of applications in the chemical and petrochemical industry, as well as in the ship building industry for the transport of chemicals. This material also meets FDA conformity.

Benefits & Features

Features

-

Resistant to creep and cold flow

-

Consistent material composition

-

High retention of the bolt load

-

Superior chemical resistance

-

No ageing of the material

Applications

-

FDA Applications

-

Fragile piping systems

Certifications

-

DIN-DVGW

-

DIN-DVGW W 270

-

Oxygen tested

-

KTW-Guideline

-

DNV GL

- WRAS approval

- TA-Luft (Clean Air)

- Fire-Safe acc. to DIN EN ISO 10497

- FDA conformity

- Regulation (EU), No, 1935/2004

Product Specifications

Typical Values Refer to 1/16'' Thick Material Unless Noted

| Compressibility ASTM F36 M | 4% |

| Recovery ASTM F36 M | 50% |

| Stress relaxation DIN 52913 | |

| 1 30 MPa, 16 h/150°C | 28 MPa |

| 2 50 MPa, 16h/260°C | 36 MPa |

| KLINGER Cold/Hot Compression Test 50 MPa | |

| 1 Thickness Decreases 73°F (23°C) | 5% |

| 2 Thickness Decreases 500°F (260°C) | 11% |

| Tightness DIN 28090-2 | 0.08 mg/s x m |

| Thickness/Weight Increase | |

| 1 H2 SO4, 100%, 18 h/23°C | 1/1% |

| 2 HNO3, 100%, 18 h/23°C | 1/2% |

| 3 NaOH, 100%, 72 h/110°C | 1/3% |

| Density | 2.5 g/cm³ |

| Average surface resistance ρO | 6.9x10E12 Ω |

| Average specific volume resistance ρD | 2.2x10E12 Ω cm |

| Average dielectic strength Ed | 3.6 kV/mm |

| Average power factor 50 Hz | 0.166 tan δ |

| Average dielectric coefficient 50 Hz | 10.6 ε r |

| Thermal conductivity λ | 0.60 W/mK |

| Color | Grey |

Pressure/Temperature Graphs

The pressure/temperature graphs shown are the most current method of determining the suitability of a gasket material in a known environment. However, chemical compatibility must also be considered.

pT diagram for thickness 2.0mm:

In area 1 the gasket material is suitable using common installment practices subject to chemical compatibility.

In area 2 appropriate measures are necessary for installation of the gasket to ensure maximum performance.

In area 3 do not install gaskets in these applications without first contacting APG for technical support service.